May 26, 2020

Asset Reliability & Maintenance in the Oil and Gas Industry Part 1: Invest in Data

Leveraging data in the right way can unlock untold benefits for many companies, ranging from understanding customers’ needs to optimizing operations. As Analytical Competitors like Google and Amazon sweep the market with unique new products and tools, many other companies are also itching to implement the newest technologies and innovative solutions for the smallest chance at a competitive advantage. More recently, oil and gas companies have begun to harness the power of data to realize greater operating efficiencies and minimize equipment downtime.

However, downstream oil and gas has a long way to go and much to gain, specifically in asset reliability and maintenance. Companies must first invest in data-driven operations to get the most value out of their reliability and maintenance programs.

This four-part series will cover the process and benefits of that strategy. In this post, we will explore three specific ways in which becoming data driven can benefit downstream oil and gas companies. The following two posts will discuss different asset reliability and maintenance strategies and how to use data to implement them.

1. Increase Savings of Time and Money

Improving asset reliability and maintenance is an ongoing topic of discussion with many companies still seeking greater cost savings and operating efficiencies. Ineffective equipment maintenance has contributed to billions of dollars in additional operating costs for global refiners due to unscheduled downtime. Furthermore, the inefficiencies created from suboptimal maintenance strategies lead to additional lost profits and spending valuable time repairing equipment at inopportune moments.

A 2019 whitepaper by the World Economic Forum indicates that leveraging data properly, like deploying cognitive computing and big data/analytics, can lead to engineering savings of up to 70% and increased productivity by up to 30%. Some companies are even utilizing digital twin technology (a virtual replica of the environment being monitored) in order to test efficiency in life cycle management.

2. Improve Safety

Safety is a mindset, not an initiative, in the oil and gas industry. The industry is often cited as having some of the most dangerous jobs in America. According to the CDC, the fatality rate was seven times higher than any other industry in the early 2000s, which explains why companies are continuing to set safety as a high priority. Poorly maintained equipment can lead to an increase in accidents, and these equipment failures have been known to cause serious damage.

Strategies for improving asset reliability and maintenance can lead to a safer work environment by catching signs early and repairing equipment before it fails. Data is vital to this effort, since sensor data and historical records will lead to a better understanding of the state of the equipment. Pairing this data with advanced analytics, such as artificial intelligence and machine learning will help experts interpret the data more precisely, leading to better predictions and fewer failures—reducing the number of accidents and saving lives.

3. Create Competitive Advantages

The current state of the oil and gas industry has created immense pressure for both cost savings and operational efficiencies. Leveraging data to optimize maintenance strategies has the promise of improving both, but unfortunately, it has been difficult for many companies to realize. This is due to aging equipment, reductions in maintenance staff, and massive amounts of data not producing actionable insights. This has left companies to implement strategies that often lead to over or under maintenance. Under maintaining decreases the reliability of the equipment, increasing the risk of failures, whereas over maintaining increases costs.

Globally integrated companies such as Shell and ExxonMobil have been using advanced analytics and technology to improve their asset reliability and maintenance strategies since the mid-2000s and are reaping enormous efficiencies and benefits. Smaller companies in the industry can ensure they not only stay relevant but even gain an edge against others by implementing these same strategies.

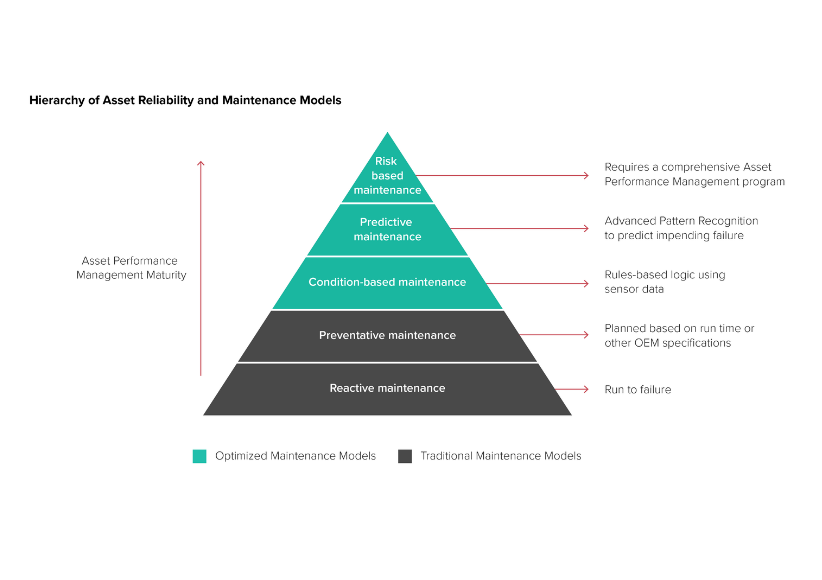

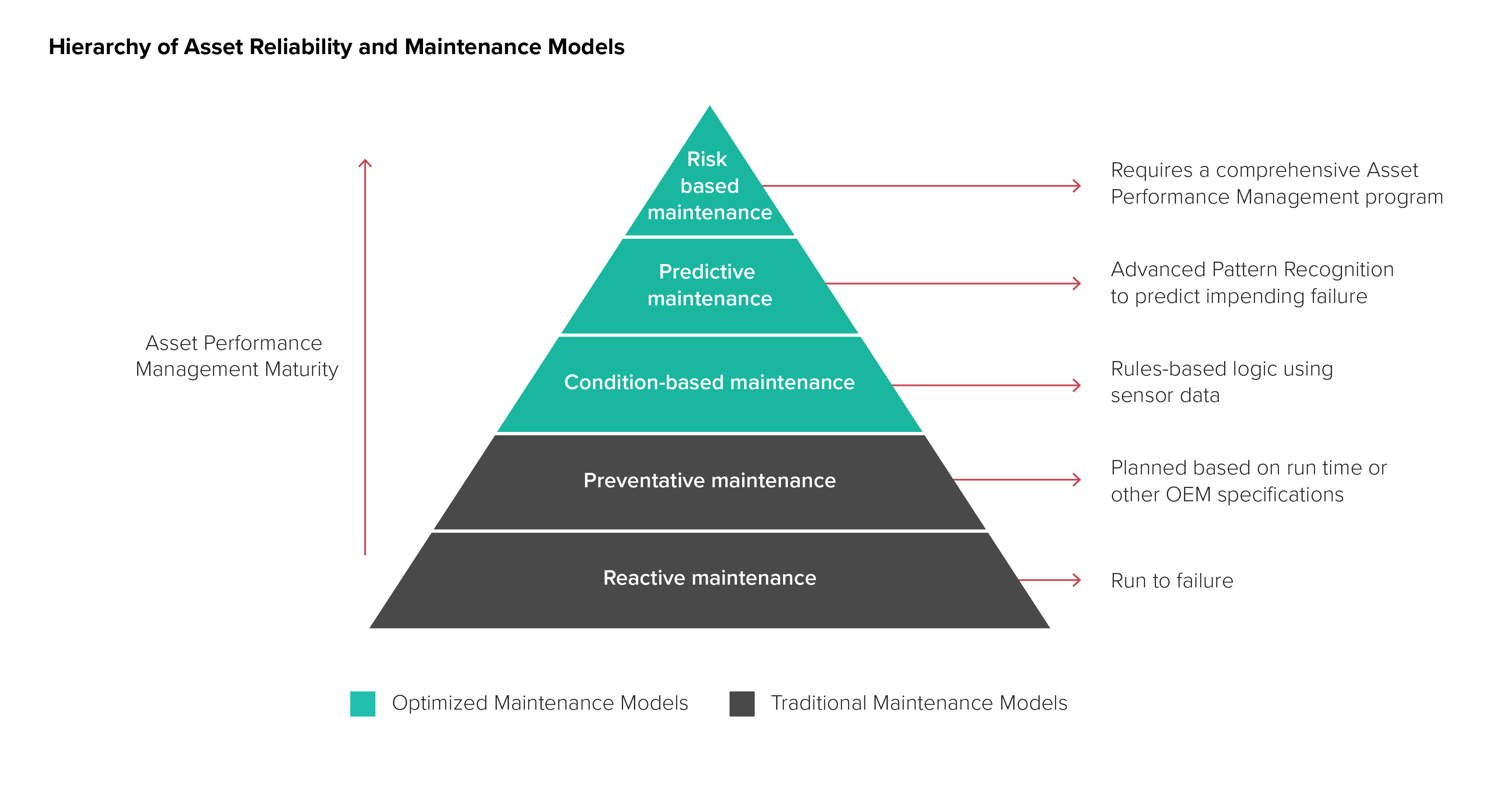

Asset Reliability & Maintenance Hierarchy

The asset reliability and maintenance hierarchy presented below shows the different strategies available to oil and gas companies. Many companies are still utilizing the suboptimal preventative and reactive maintenance strategies due to aging equipment, the lack of a data strategy, and cost of new technology implementations. These two approaches are potentially keeping companies from realizing a true competitive advantage.

Taking the First Step Toward Being Data Driven

Despite these barriers to entry, opportunities exist to move toward the optimized maintenance strategies and realize greater efficiencies. These models—along with leveraging advanced analytics, artificial intelligence, and machine learning—are prime examples of how downstream oil and gas companies can reap the benefits of becoming data driven.

If you are interested in hearing more about leveraging data correctly and what it means for oil and gas, reach out to marketing@credera.com.

Check out part 2 of this series, which covers the three optimized asset reliability and maintenance models and how to leverage data properly to implement them.

Contact Us

Let's talk!

We're ready to help turn your biggest challenges into your biggest advantages.

Searching for a new career?

View job openings